I’m into this 65+ hours and no closer to a solution.

The table has 24 in drop leafs. I currently am supporting it with two 29 in long 1/8 x 1 in angle iron.

I getting 1/4 in deflect with only 20 pounds.

Suggestions?

I’m into this 65+ hours and no closer to a solution.

The table has 24 in drop leafs. I currently am supporting it with two 29 in long 1/8 x 1 in angle iron.

I getting 1/4 in deflect with only 20 pounds.

Suggestions?

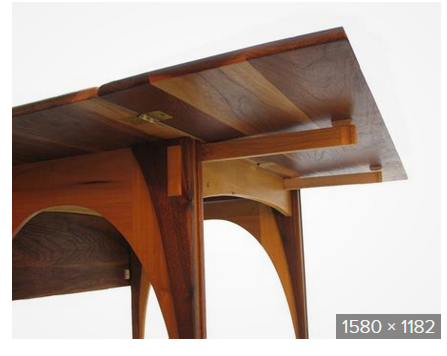

Great looking table top. Do you have some pictures underneath of the hinging/supports of the drop leaf? A good test of the angles would be to clamp them to your work bench extended the same as your table and put the weight on them and check the deflection., include 1/2 the weight of the leaf.

Also when the leaf is up is there any binding at the hinge edge?

Herb

Thanks Herb. I just added more pics

I presume the angles are slid in and out, and to do that there will have to be a slight clearance for the angle to slide, This in itself can create some deflection at the outer end. And since they are loose to slide there will be a little play and that will be doubled at the end.

Have you considered the folding braces? they are rated at 50#.

Herb

I would take a look at hat channel. If you are not familiar It is a U shape with wings, think 2 Z channels stuck together. The extra bends help greatly with rigidity, and it has the added benefit of being aluminum and reasonably attractive. Really popular for stiffeners in aerospace. You can capture the wings in a groove to further stiffen the assembly. The other thing you might consider is a tapered shim for the rail to ride up on so it preloads the rail at the end of the travel. Just guessing but this is a bit like a problem I had some time ago.

My guess that tube steel or 1/4" angles, rather than hat channel would be

stronger, the tapered wedge,attached to the underside of the table is a good idea too. All the hat channel that dry wallers use is galv.steel, it might be stronger . How about an oak 2X4 at the center. I still can not see how the support is slid out. Do you reach under and slide out each side individually?

Maybe attaching a 1/4" bock to the end of the angle might work too

Herb

I didn’t see ones long enough. The leaf is 24in

Mark your leaf is quite wide. try adding a 1/4" thick spacer under the table on the out board end. see if that corrects the sag. If it does, make a wedge block and see if that will work to raise up the table top and fasten it under the tabletop such that your struts ride up on it and wedge up the top.

Usually tops that wide are supported by a fold out leg,or a fold down leg.

Herb

I think a 24" leaf is just quite large, and you might have to live with some sag.

If you want to improve it, you’d want to find where the deflection is coming from. Either the steel is bending, or one of its supports is giving way.

If the steel is bending you could look for a stiffer component. If the supports or top are deflecting hard to go into detail here about how to address them.

You might just grab a beer and pull a chair up to an extended leaf. If you can hang out and not feel like your beer is in jeopardy, maybe just live with it ;-]

change out your current slides to HD drawer glides…

there are many different styles that will accomplish what you are trying to do w/ minimal deflection…

.

there is another way to fix your issue…

use load rated table extensions…

.

I was at the Stickley Museum a few days ago, and they were using a solution I haven’t seen mentioned here. It’s probably too late but still interesting.

This is three tables side by side. The middle one has hinged leaves on both sides. To support it, they have a third leg that in this position is folded next to a regular table leg. When the leaf is up, the leg swings out to support the leaf pretty far out, in its center.

Here’s a close up shot:

Let me know if that’s not clear.

I’m also curious to hear how you ended up dealing with the problem.

Nice find Tim… great solution too…

me too…