I am seeking a fluting bit with a 3/8" radius, but less than 1" cut length. Its for finger grips in a cutting board. The ideal one would be the Woodline WL-1475 but those are out of stock. Freud, Amana, Rockler, etc. don’t have one. Grizzly has one that’s close but I’d prefer to see it before buying. Does anyone have suggestions of specialty stores locally that may have such a bit? Thanks in advance for any suggestions.

Hello…

Look to ball nose or half round bits…

Are you asking for a maximum depth of cut?..

Depth of cut is either controlled by the bearing dia. or by the depth setting on the router…

For edge work w/ a hand held router and the absolute need to stay straight and clean try this router setup…

The smaller the router you use the easier it is to pull this off…

Or a ball nose bit, some stops, and a router table. Multiple passes could give you whatever depth you need.

Larry,

I’ve purchased and used this bit on my CNC, through Amazon, of course?! :

Amana Tool 45918 Core Box 3/4-Inch Diameter x 7/16-Inch Cutting Height x 3/8 Radius x 1/4-Inch Shank 2-Flute Carbide Tipped Router Bit

I’m very satisfied with these Amana Bits, and recommend them. I con bring one into our meeting Dec. 5 if you need to see it before purchasing. I couldn’t find them locally. When using it for Fluting, I often use my Router Collets as ‘Top Bearings’. As for other local suppliers, in the past I’ve found some Machinist Tooling places in South Seattle, which may have something. But, I don’t have any specific business in mind for this large Diameter Bit.

F.Y.I. For Those ‘CNC-ites’ these Core Box bits are great for rough Carving and save much time over small diameter End Mills and Ball Nose bits Just watch out for undercutting with it’s edge – I can explain this caution better in person, in December.

John

Thanks very much for your thoughtful reply John. If the sides were straigth-edged, this bit could certainly work. However, the sides of the board are curved…I currently route the grips with the board flat and a template surrounding the bit that is protruding from the table. To use the bit you describe, I think i’d have to hold the board vertically and “roll” the board across the table. I’m not sure how do to that!!! Can you think of a way to use this bit for a curved surface?

Sorry, Stick and Craig, I didn’t see your rep,ies at first. I am using the router table, template, and stops to do the cut. Currently using a bit like the ones here

But it’s not deep enough. The maximum depth should be about 5/16 - 3/8. The maxiumum height is 3/4 since the board is only 1" high.

Change the dia. of the bearing…

Larry,

Reviewing the post(s) by Stick etc., this may be your best option, with the Box Core bits. I suggest you use the work piece to make exact edge/surface guides that can be clamped the the top & bottom surfaces, possibly of mdf. Then use the two fence method to route the finger groove, or use the offset router base collets as I suggested between the mdf guides. If the groove has a straight bottom, just make the mdf guides I suggested straight vs. curved.

If this is a long-term need, mounting the router horizontal and using it as a “Mortising Table” may be something you might consider.

Good Luck,

John

THanks so much for the great suggestions. Since I already have one MDF template to assist in the curved routing, I will try STicks suggestion of a 3/8" bearing guide to replace the stock 1/2" on the fluting bit and see if that gives us enough depth. If not, maybe then I’ll try using the Core Box bit and flipping the piece. Will report back the results

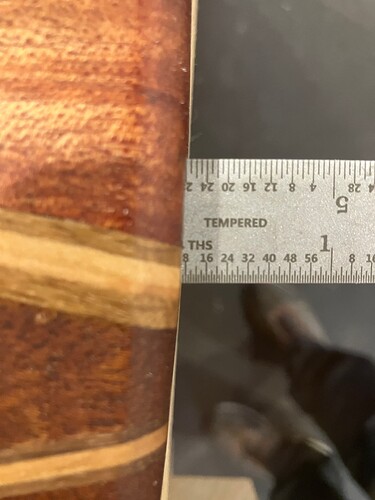

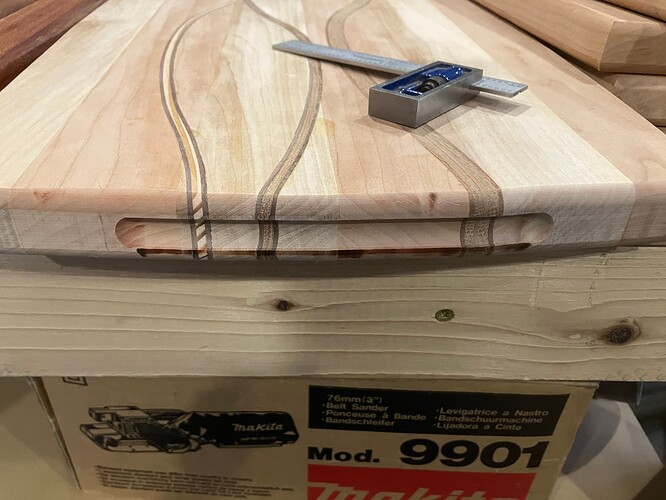

Finally working on the second batch of boards and used the 3/8" bearing guide today. Definitely got some more depth of the finger grips on the ends of the boards…see the depth in the two photos. Unfortunately since it’s a 1/2" shank, there was a little burn on the bottom of the cut where the board rubbed against the shank during the routing cut. But I can sand that away. Thanks again for the suggestions!!

Consider using the burn as an accent w/ some careful sanding…

Pre-tape or wax before you route…