Hi all.

I’m planning on making a gift for a scout friend with this block of pine. The trees were in a forest fire in Oregon a few years ago and milled into lumber that is being used for a timber framed structure he helped build at the scout camp in Monroe.

1, yes I’m still working on my kitchen remodel.

2, do i need to be concerned about any bugs?

not likely…

but, if has laid around for some time in a wet environment. look for bored holes, stain splotches or mini piles of fine saw dust…

If it’s been drying for a few years, I assume all the bugs are gone. If you’re concerned, you could dry your board in the oven. It looks like it might just fit, or at least the boards required for that clock should fit. I’ve never done it, but there’s plenty of info out there.

Drying…

Preheat conventional oven to a temperature of 215°F digitally or 218°F analog… Check it often and adjust it accordingly…

One rack goes to the bottom of the oven w/ a baking pan on the bottom rack to catch the drips… (resins)… Cover the pan w/ aluminum foil to help w/ the clean up,

Another rack in the center of the oven for the wood and oven thermometer… Put the thermometer in the far back corner…

If your oven has a convection fan, turn it on, airflow is a major plus…

The wood goes on the middle rack, bake for one hour… Don’t let he pieces touch so that you get more of a uniform drying… If you chose to stack it, sticker it…

Test the moisture content after an hour, reheat for in increments of 15 minutes until you reach your target MC… Once the MC level is stable remove the wood and allow it to cool… Use a cooling rack… Your target MC should be around 6%…

if you prefer to use your microwave…

MICROWAVE OVEN WOOD DRYING.pdf|attachment (23.0 KB)

Notes…

Apply a sealant or wood stabilizing solution after it cools to room temperature so that it remains dry… After drying wood acts like a sponge and suck up humidity like a sponge…

Drying wood can cause it to crack or warp… Dry larger/longer and more pieces than you need or you may have to do the process again w/ more wood…

If you have a digital moisture mere you are golden… Take readings before during and after…

If not - weigh it before during and after…

Weighing for MC… (the numbers are hypothetical, not the formula)

Moisture Content %() = (weight of water removed ÷ by ovendry weight of wood) x 100

Wet weight is 120.00g and oven dry weight is 99.99g, then the loss is 20.01g. The MC is 20.01 divided by 99.9, which equals .200. You then multiply by 100 to get it into percent form, since we always talk about “percent MC.” (So the answer, in this example, is 20.0% MC.)

Typically a MOISTURE SECTION is about 100 grams (g), so you need a balance scale that weighs to/in 0.01 grams if you are to get the most accurate readings. However, 0.1 is fairly close (within .2 percent MC usually)…

MC…

HOW MUCH MC…pdf (31.0 KB)

how is that proceeding???

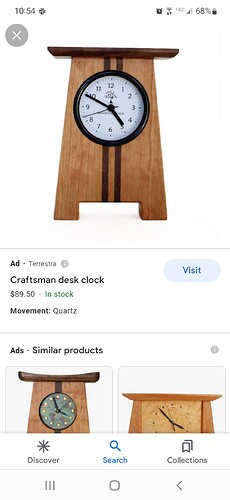

Nice looking pine,Mark, you are getting some nice shavings off of it. Pine is a pleasure to hand plane. It will make a great clock.

Herb

Today i was making the last two parts for the cabinets and cut the screw blocking 1 inch short so i called it a day.

Yeah. That’s a lot of work I probably won’t do.

what’s a lot of work???

All that stuff about the oven.

OK…

when you go to build your clock please make sure your MC of the wood is 6~7%…

That blue is a fungus introduced when the pine borer beetle drills through the bark and allows it to enter. The beetle holes are typically fairly shallow, while the fungus goes quite deep and so you’re probably safe. We saw a lot of this at the sawmill I worked at outside of Boulder, CO. It’s much more common now that climate change has led to warmer winters.

Typically that stain does not last however, it will fade over time especially if exposed to much UV.