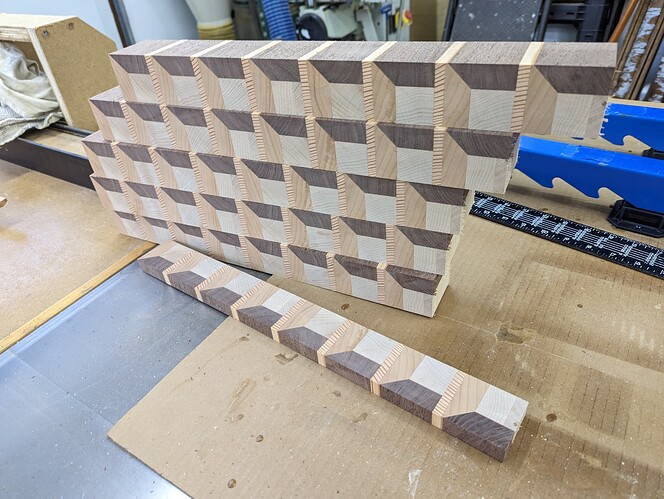

Not rocket science, but definitely surprising how visually effective this pattern is. Although conceptually pretty straightforward, if it’s going to last in the kitchen I think the precision in milling is critical. Afterall, you can’t really joint/plane the glue-ups without compromising the pattern.

I had a wedding coming up Saturday, Monday I realized these boards could do the trick. Maple, Walnut, Cherry.

The walnut and cherry were milled to strips 3/4x2. The maple made square stock 1-1/4 on each side. Rip a 45 on the darker woods, then glue up these strips with a combination of plastic wrap and clamps. I try to avoid 1 off plastic use, but it was pretty key here to keep everything aligned.

Then those assemblies were glued up with a narrow strip of Doug Fir between them. That slab I cut in half, and joined again with more DF

Then the typical end-grain procedure of cutting the slab into 2" strips, and flipping each of those before yet another glue-up

Here are the strips fresh off the saw. Even without the final layers of DF you can start to see the 3d illusion

Final product with grooves and tung oil:

I will pay more attention to grain next time. I think I got lucky with the Cherry and DF, if their orientation wasn’t consistent (which I wasn’t paying attention to) it would have not been the same end product.