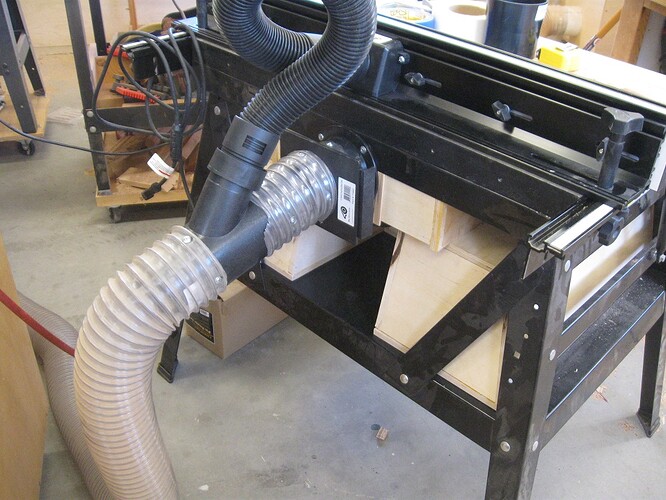

Here are some pictures of my router table DC system. The first is the Jessem table .It has an old 3hp PC motor and a jessem Master lift. the router is plugged into a speed control on/off switch. so I set the router switch on the hi speed since I can’t get to it under the table. Then I made a box the motor protrudes through the bottom for air through the router motor. The cutout for the motor lift is larger to allow air flow for the dust collector. Then the DC hose on the back Wyes off with a 2" that goes to the fence. behind the bit. There is also an adjustable opening in the side of the box to adjust makeup air for a good airflow in the duct.

Why you ask? Because if there is not enough air flow in the duct, on long runs the chips can settle out in the duct,thus eventually causing total decrease of airflow in the system.

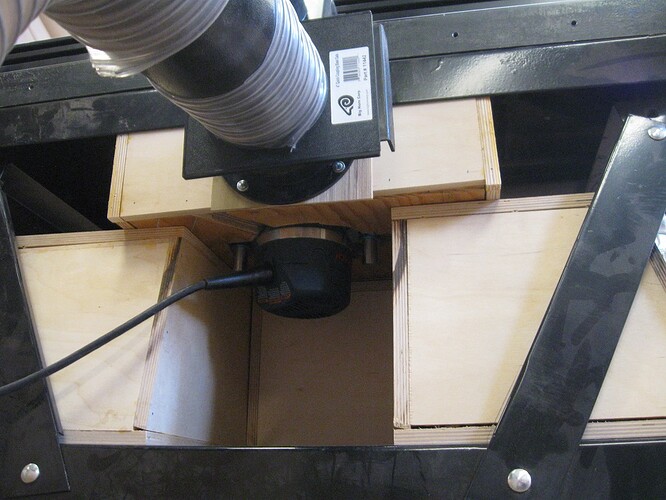

The second picture is the MCLS router table. I did the same and also put drawers in both tables. the MCLS table also has a Rockler lift

Herb