Herb and I took some ideas and tuned them to our needs for dust collection on our router tables…

the start and evolution… As usual we’re always up to something…

Venting a router table’s motor w/ DC…

This is by Stick486

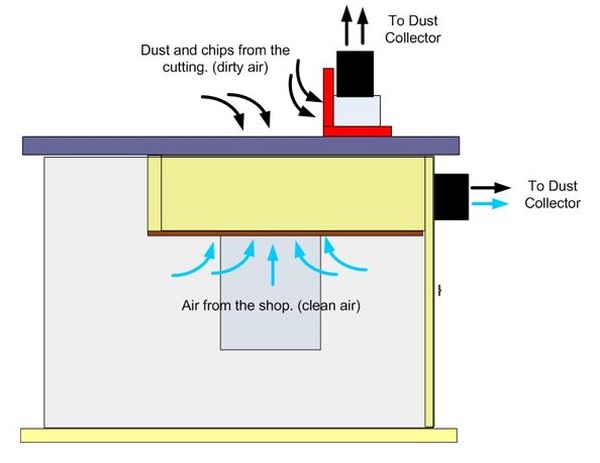

One very important thing you have to remember is to make sure your router box is vented w/ outside air for the motor or you will cook the motor from excessive heat because of the lack of cooling air for the motor…

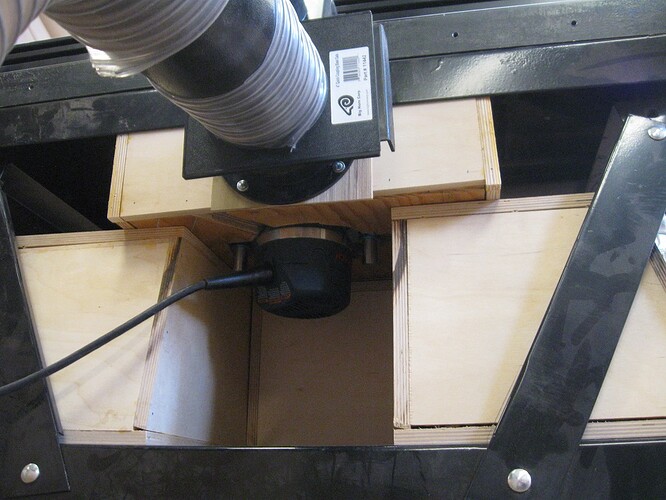

Do this by either sticking the motor’s air intake outside of the box or add a ‘‘snorkel’’ to the end of router motor…

The DC alone puts the enclosure at a lower air pressure than the air outside the box. You may be sucking across the base past the bit but where does the makeup air that is going through the router’s fan come from? Air is being sucked out of the box with no intake near the fan inlet at the other end of the router.

Also, the router’s heat is exchanged to the air molecules passing through the motor. A DC lowers the pressure in the cabinet, in turn, reducing motor’s heat transfer…

Different routers provide cooling differently…for example, the Bosch 1617’s internal fan blows air directly upwards (whens mounted in the table) versus the Triton router which diverts air sideways as it exits the router. The Triton also diverts air away from the insert and it’s dust collection plasticware under the bit…

Equally important is dust not entering any of the components in the router as a result of it’s internal cooling system. This includes switches, slides, armature, etc… This can only be determined over time for the different varieties of routers and their cooling configurations.

There are two separate systems going on. First the air flow requirements of the router need to be satisfied. Secondly, the dust collection system needs to do it’s job. I can state categorically that any compromise created as a result of mixing the two is just that…a compromise.

That dust enters the box is a dust collection issue. Edge profiles versus bottom profiles (grooves) create different dust problems…

All this assumes that one has worked diligently to separate the two systems. The Snorkel approach does exactly that. It keeps router cooling separate from dust collection…When using the snorkel, the positive pressure created by the router’s internal cooling needs to be equalized in the box…that is the reason for allowing some suction from the dust collection system to evacuate the box’s otherwise positive pressure. If you separate the two systems, there will be no opposing air flows…except for evacuating the positive air created by the independently supplied airflow of the router’s cooling system.

This is by Herb Stoops…

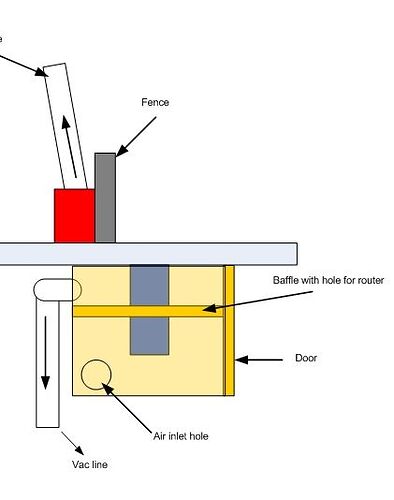

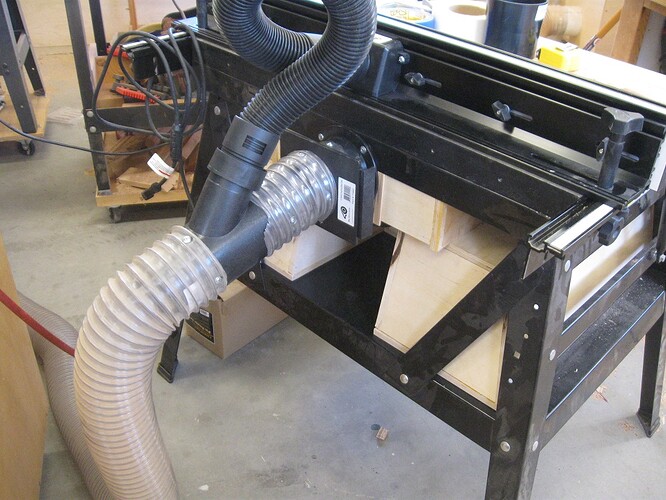

That is a good point, Stick, I let the router protrude through the bottom of the box. By doing so I had to cut out the bottom to clear the posts for the JessEm lift. I like Stick’s idea better to clamp a flex hose around the router and let it protrude through the bottom of the box to allow the motor to suck clean air. I also have an adjustable port in the side of the box to allow more air into the box to create a maximum air flow through the box.

In my first router table I had the Milwaukee router, it was a real workhorse, the reason I bought the Milwaukee was at that time it was one of the few routers you could adjust the height from the top of the table. I didn’t have a dust collection under the table at that time and could reach under, unlatch the router and do the adjustment from the top ,then reach under and lock the router. But the amount of chips and dust that ended up under the table was a large amount. The fence dust collection just couldn’t get half the chips.

I also doored the router box for easy access to the router and the lift…

Stick did the same and he installed his vents in the door…

Under the table DC is a must, I branched off a 4" diameter hose with a 2½" take off to the fence and the 4" line to the underside of the table’s box.