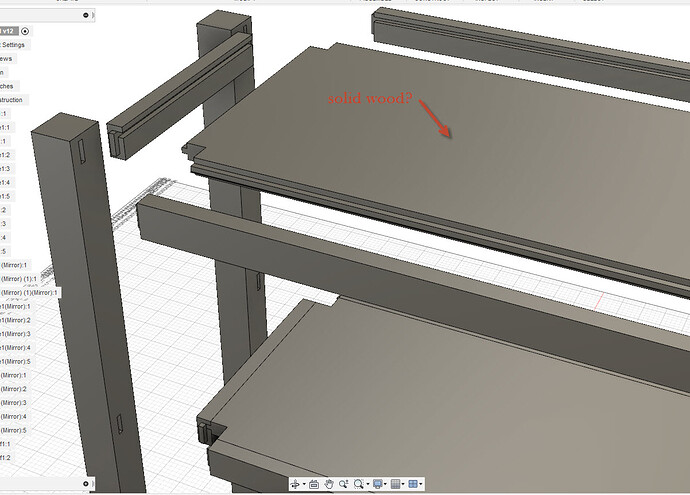

I’m planning on building a Parson style bookcase and wondered if I can use solid wood for the shelves that will be bounded. Or should I be worried about wood movement and use plywood? Plan is to use Cherry. Ironically a 4’ x 8’ sheet of Cherry plywood ($9:16 bf) is more expensive than 4/4 Cherry ($7.20bf).

welcome to North West Louis… we’re glad you’re here…

YES!!! you certainly can use solid lumber instead of plywood… it will make for a much nicer project…

are you planing to make up a panel for the shelf or use a one pierce board???..

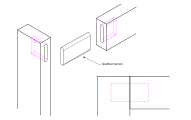

for panels use splines in lieu of T&G as well for the bounding and float (aka feather) the M&T’s… these processes will cut way back on the waste and save you in material… each spline will save you from wasting ½~¾" of material per joint… the floating tenons should save you at a minimum, 2" of length per rail and stile…

in the grand scheme, this can add up to a lot of material…

narrow boards instead of a one piece plank will do better at limiting wood shape changing and movement better… you will find that that there will be a lot less computations to make over all lending for less chances of measurement errors… your measures will be actual and not something plus something… take safer less math route…

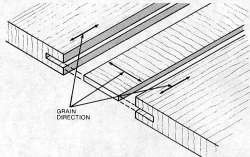

for splines I find that using thin Baltic Birch Plywood strips (3~4MM thick) work better than 1st rate and are next level strong nor will the split/crack/shrink/swell like natural wood… using BB ply for the tenons is a major plus too… if you need thicker tenons or splines, laminate multiple layers of BB ply to your happiness… BB ply in theses applications won’t be grain orientation sensitive…

normal wood splines, as a rule of thumb, are 1/3 (± a skosh) the thickness of the material you are splining… the tenons - ½~¾ the thickness… floating tenons make for easier error correction for loose or misaligned M&T’s w/o having to “rework” the joint…

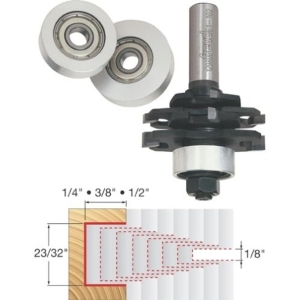

to cut the splines use your TS or a slot cutter… I prefer a slot cutter for this task… shown is a stacked cutter which the cutters can be use singularly or in tandem (stacked) to get just about any width slot you could desire…

a strong benefit to using splines is the your joinery will auto flush giving you a flat panel…

TIP…

lay out your boards aesthetically, using chalk, mark the orientation of each board to each other and whether you are looking at the top or bottom of the panel… (I flip the boards and mark them as bottom)…

to maintain coplaner when you cut the slots, the top face always faces the fence if you use your TS… if you use a slot cutter, the router rides on the face… this way the slots are kept in as near alignment w/ each other as possible…

a bit more on the splines…

the M&T’s…

Rule of thumb for mortise-and-tenon size.pdf (71.4 KB)

Thanks for the info. Greatly appreciated.

yur welcome…

was it way too much???..

Not at all. My biggest concern was lateral wood movement in the shelf boards. Wanted a sanity check on that. I agreee that side joining a couple of 7" wide 4/4 boards to get a 13"+ shelf will cut down on that risk. I’ll likely use biscuits on the side join as that is what I’m used to. And Mortise and tennon on the styles/rails as that is what I have. I’ve considered getting a domino set up but don’t really do enough to justify purchase (the lathe is my favorite tool in the shop).

ripping those 7" in half length wise and splining them back together will greatly improve your odds…

I retired my biscuit joiner decades ago in favor of splines… I felt I was getting substantially better results w/ splines…

hopefully you will share your work and techniques w/ us… please…

Have a look at my web site for a sampling of my stuff.

YOWZER!!!..

WHEW!!!..

WHOA!!!..

I admire your above my pay grade talent…

your jewels need a thread all by their lonesome…

I did…

I do not know how to tell you how thoroughly impressed I am by your work…

Thanks. How about you? Where can i see your stuff?

I’m more of the nuts and bolts type…

I’ll dig up a pic or two as I haven’t a web site…

@HerbStoops

you might want to get in on this thread…

Welcome to the forum, Louis. I like your website and the work you do is outstanding in my book.You do beautiful work and your choice of projects, wood and finish is top line. We can learn a lot from you. Be sure to show us how the book case comes out. Some progress pictures would be more than welcome too.

Herb

Wow, what an Artisian you are. Im humbled.

That is a nice job on the house,Stick, The Medallion is outstanding I step up every time I look at the picture,even though I know it is flush with the floor.

The dining room furniture and the china cabinet and writing desk are very fine furniture in my book too.

For me it is a pleasure to see work like yours and Louis’s, kind of like browsing in a candy store,or tool catalog.

HErb