for you gardeners…

54d113af09c82_-_arbor-final.pdf (1.7 MB)

Easy Bench Plans.pdf (132.2 KB)

I have the plans for this arbor in PDF that’s too large to post… I will email it if you’d like to have it…

for you gardeners…

54d113af09c82_-_arbor-final.pdf (1.7 MB)

Easy Bench Plans.pdf (132.2 KB)

I have the plans for this arbor in PDF that’s too large to post… I will email it if you’d like to have it…

another for those that love the outdoors…

Make Your Own Canoe Paddle.pdf (158.3 KB)

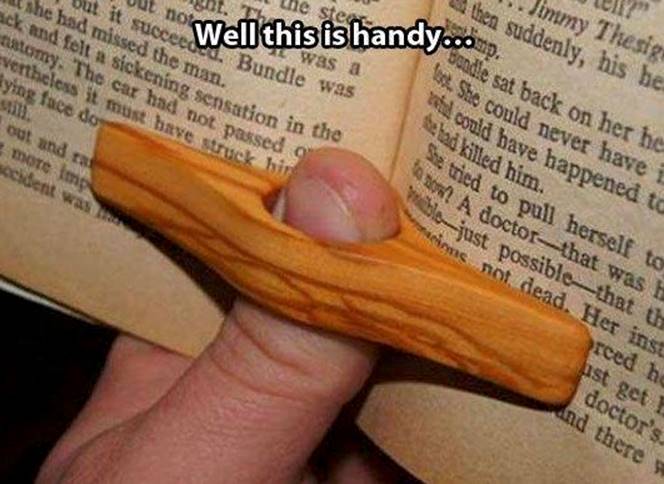

are you a reader???..

this may help you w/ your pastime…

Did the Dr. make it there in time to save him? Only the Shadow knows…

Herb

Wind Chimes, those things that foster love/hate relationships…

correctly done, they are very pleasant…

here is a link to an open source on wind chimes…

there is more information in this link than you could ever possibly imagine on design and building…

here’s a PDF that covers the basics…

WindChimes.pdf (232.7 KB)

one that is a bit more advanced…

DIY Wind Chime Sets by Lee Hite.pdf (1.0 MB)

I was never good at music,couldn’t learn to play any instruments,including a wind chime.

But lots of good information there.

Herb

we’re about the same…

I can’t carry a tune in a bucket…

When I was growing up on the farm, I used to sing to the cows as I milked them. They gave me all their milk fast to shut me up. Otherwise they held back on me.

Herb

it was that or get side kicked…

I know this isn’t WoodWorking but when you go afield to harvest wood being protectively dressed is important…

I would like to introduce - ‘Tincloth,’ - it was invented in some year by some body – who needed something tougher than canvas or denim – and tough enough for fighting dragosaurs with a claw hammer on horseback during their trek across the Great Plains and into the mountains… they wanted to stay warm and dry too…

Tincloth is that kind of tough stuff…

For the outdoorsy-ness in you a very good extremely weather resistant clothing is called Tincloth… Quality Tincloth is very expensive to buy… Some know it as Oilcloth…

a coat and ilk similar to the heavy canvass clothing that Carhartt and others offer is an excellent starting base…

you can make your own chaps, leggings, vests, bib, overalls, jackets, coats and slickers into tin cloth… what ever your needs dictate,

Tincloth is made by coating canvas in an oil wax mix that dries and hardens, (but remains flexible) namely beeswax and boiled linseed oil…

The Mix - Equal parts of…:

beeswax and boiled linseed oil (BLO) at a 50/50 mix by liquid measure…

some use 50% wax, 25% BLO and 25% turpentine… I think the turps adds weeks to the dry time and it stinks for about forever…

Mix the melted beeswax and into the linseed oil… Keep in mind it doesn’t need to reach a certain temp, just be hot enough to ensure that it becomes a fully liquid well blended mixture…

‘‘paint’’ a thin coating of the mixture onto your cloth… a utility nylon scrub brush is just the ticket here…

Use a hair dryer (set to medium to high) or heat gun (set on low to medium) to ‘‘melt’’ the mix into the fabric…

let dry…

Note: Be very careful not to burn the fabric… but the finished garment is flame resistant but not fire proof…

tomorrow re-coat the fabric w/ a 2nd thin coat of mix and ‘‘melt’’ this coating into the 1st coating for blending. A 3rd coating is totally optional…

Notes:

Keeping the mix ‘‘warm’’ during application is a big plus.

Use a double boiler or a crock pot set up as one to do this.

Scrape away the thick/heavy blobs using a credit card or a stiff plastic squeegee/putty knife, they work well… avoid using metal… a thin piece if plywood w/ some flex to it works well too…

after squeegeeing remelt your coating to improve blending…

Saving left over mix works fine… Just reheat the solids into liquid for use… if you use a metal can you melt your mix by setting the can in hot water double boiler style

Melt the wax into your heated BLO… Using shaved wax is easier to melt and blend.

Apply only enough heat to make/maintain a liquid.

Make sure your cloth is clean or you will have permanent dirt.

Heating the cloth w/ a dry iron before mix application is a plus.

Do sectional application at a time.

Do the work in a well ventilated area.

BTW, toilet wax ring gaskets ARE NOT true wax… they are made from vegetable and petroleum waxes as well as polyurethane additives…

DO NOT substitute or you project will fail…

food spills on tincloth don’t want to stick or stain - they do clean up/off really well…

My Dad had a pair of pants and jacket when he worked in the woods in the 1920’s and wore them when working on Grand Coulee Dam and later.

I wore them as a teenager, but not too much. They were double layer then and very stiff, They wore me out after a day wearing, but kept me completely dry working all day in the rain. There was a sow wester type hat that went with them. They will last a lifetime, never seen them go in the washer either.

Herb

My set is older than dirt… 60 years or so,

if you use BLO and real beeswax they aren’t so stiff… caning wax lends to stiffness… other than beeswax - all bets are off…

the chaps are thorn proof…

I even did my sleeping bag cover…

food, ice and rain won’t build up on them… mud and plain dirt just brushes off…

you know how ferocious the weather gets here…not problemo…

I did several styles of hats too … Baseball and bush hat,….

Indispensable cutting boards…

they hard to beat as gifts or for use in your own kitchen…

cutting boards.pdf (788.8 KB)

Food-Safe Finishes.pdf (51.5 KB)

They are fun to make too. Another project for “scrap” wood. Like someone once said,“there is no wood scraps, only no place to store them”…

The more you make ,the more creative it gets.

Herb

These are only a drop in the bucket…

Have a few nice nick knacks you’d like to group display???

this may be what you were looking for…

the measures shown can easily be changed proportionally to fit the need as well as the return angle of the shelves…

3 TIER SHELF.pdf|attachment (10.7 KB)

why not???..

we all have some precious tools that deserve the hand crafted best…

Machinist’s Tool Chest.pdf (1.7 MB)

For the artist, the children or to display…

Single mast tabletop easel plan.pdf (3.0 MB)

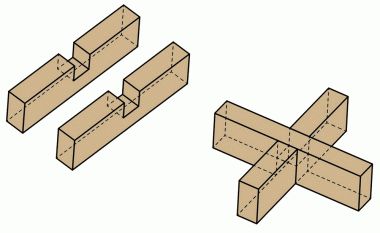

for your next table top or shelf do it in torsion grid…

using edge half lap joinery is far superior to making one from blocks…

super strong, tough and in comparison, light weight…

shelves only need 3~4MM plywood, door skins, luan etc for the skins…

they can be made ultra flat…

use construction adhesive instead of glue for better results on the core and for fastening on the skins…

Edge half lap joinery…